5 Tapes for all measures of safety.

- Jumza Offra

- Oct 19, 2022

- 5 min read

When putting together a safety plan for a factory, warehouse or other facility it is important to start by looking for ways to prevent accidents. It is no surprise that many accidents are the result of people not realizing they were in the wrong place at the wrong time, or just not being able to see properly where they were going. It is an unfortunate reality that in many of these facilities you simply can’t see due to lack of lighting, sharp corners or other distractions. While you can’t always fix those problems, you can minimize the risk by adding reflective tape to the area to help ensure warning of potential dangers.

Tapes are used to promote safety in a variety of ways, from creating an airtight containment during an abatement job that prevents the spread of airborne hazards like mold and asbestos, to protecting electrical splices properly to prevent electric shock. Tape is also used to mark hazard areas and create boundaries to prevent entry into danger zones. Today we will be focusing on tapes that are specifically designed for the purpose of safety and hazard marking.

FLOOR MARKING TAPE

Manufacturing plants and other industrial facilities rely on floor marking tape or warning tape to promote workplace safety. In these types of job environments, working in close proximity to heavy machinery is a daily occurrence – and an injury could occur at any moment.

Floor marking tape is often used in the types of industrial facilities where loud machinery is constantly running and earplugs are worn by workers, making it difficult to communicate by speaking while on the job. In these environments floor marking tape draws employees’ attention and reminds them to move carefully as they navigate through the area.

The Color Coding System

The use of floor marking tape is promoted by OSHA or the Occupational Safety and Health Administration and along with it is the specially designed color coding system to facilitate better communication. Here are some of the examples of colors being used in floor markings along with their meanings:

REFLECTIVE TAPE

Reflective tape can be used in a wide range of areas for many different reasons. It is most useful when in an area which may not be brightly lit and people frequently travel through the area. Whether with a flashlight or the headlights of a vehicle, reflective tape can help alert individuals to danger with plenty of time to take action to avoid it. It is important to keep in mind that it throws/reflects light sources and doesn’t produce light itself.

There are many different places in just about every facility that could benefit from reflective tape. Of course, each location will be a little different, but these general ideas can help you figure out exactly how useful this tape can be.

Dark Corners – No matter how much effort is put into lighting, there will always be shadows in factories and warehouses. With this in mind, adding reflective tape to dark corners can help alert people to the fact that the path is about to end. This is important when people are carrying heavy objects or driving through the area in a hi-low or other vehicle.

Parking Lots & Company Roads – More and more public roads are having reflective objects placed between lanes to help drivers avoid accidents, and it just makes since to do this for roads in and around your facility as well. Many locations have drivers who are moving large objects which make it hard to see so having reflective tape to follow in the dark can really save the day.

On Clothing – When people are passing through areas in the dark it can be extremely helpful to have their clothing marked with reflective tape. Many companies will place this tape on the coats which people use since it is inexpensive and can be quickly replaced.

On Vehicles – While it is critical for drivers to see where they are going and any people around them, it is also needed on some vehicles with low-lighting that could hardly be noticed as they move through the area.

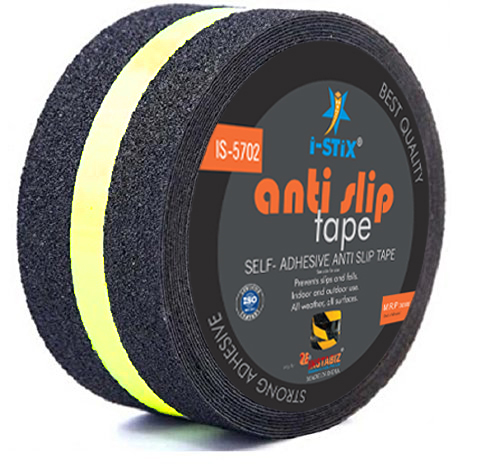

ANTI SLIP TAPE

Anti Slip tape, also known as Traction tape, can increase the safety of the walking surface itself. Anti slip tape, which comes in a variety of colors and widths, is usually used on surfaces that are frequently wet such as entryways, showers, locker rooms, or areas near drains. Depending on the level of traction needed, organizations can select from a variety of grit levels.

Anti-slip tape is available in a variety of colors, patterns, wordings and dual strips which can also serve different functions. For instance, brightly colored tape can help workers find a consistent foothold in a poorly lit stairwell. Coloured anti-slip tape can also be used by employers to help meet their floor marking and hazard identification obligations. Employers at warehouses and many other work settings are legally obligated to use color-coded floor markings to warn employees of specific hazards. For example, black and yellow striped anti-slip tape is commonly used to warn employees that an area presents a physical or health risk.

GLOW IN THE DARK TAPE

Glow-in-the-dark tape serves a unique purpose. It helps people find their way to exits during a power outage. In low-light areas, glow-in-the-dark tape can also improve visibility during regular operations. This tape, also called photoluminescent tape, functions by absorbing energy while the lights are on and emitting that energy back out as light when it’s dark. That means this tape will work well in most environments, but it’s important to remember that in places where there’s never much light, it won’t be able to charge properly.

For certain areas, for example marking a emergency exit where there are chances for power outage, i-stix® offers photoluminescent tapes with exit and arrow marking tapes to provide proper directions to the exit in case of an emergency.

FLAGGING TAPE

Flagging tapes are used to mark these potentially dangerous areas and hazardous materials that may be present on the jobsite. It is easy to make the assumption that an area is safe when nothing is marked as a hazard, and when every minute counts, it can be a pain to recheck work done by someone else before starting your own project.

Flagging tape is a useful tool for marking the kinds of hazards that are commonly faced in construction zones. Each color even has its own meaning – red indicates the presence of electrical power lines and conduits, yellow represents gas or oil, and so on. Using the right color is important because there may be different precautions and safety procedures that need to be taken depending on the type of hazard involved.

MORE THAN WHAT MEETS THE EYE

Construction or industrial sites can be extremely dangerous, even for professionals. In areas where there is a high risk of low light as well as potentially slippery surfaces is where you’d have a dilemma on which tape to choose... Anti Slip + Reflective Strip or Anti Slip + Glow Stripe or Anti Slip Glow Tape might be just what you need. This tape offers the best of both tapes, In the event of a power outage, the glow tape would be extremely helpful in lighting dark corridors or pathways to exits that would not otherwise have access to natural light along with provide traction to help people avoid slipping. They can serve double-duty by directing the flow of traffic, detect the path , or help people establish grip.

WHAT ARE THE BENEFITS OF USING SAFETY TAPES?

Simply put, they help you create a safer workplace. Adhesive tape can be used to draw attention to potential hazards, including low ceilings or low-hanging objects, a step or leading edge, potentially dangerous or broken equipment, or an area where something spilled on the floor. Safety tapes are an easy way to provide a visual guide to help people move safely through a space or to create a boundary around a place you’d like people to avoid.

Whether the nature of your job causes you to come in contact with potential dangers on a regular basis, or a special project requires some extra caution, tape can be a simple and cost-effective way to help reduce preventable injuries and the costs associated with them.

Interested in buying safety and marking tapes? Contact InstabizSolutions.com.

댓글